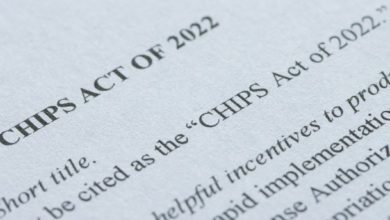

On 10 June, bipartisan legislation was introduced in Congress to encourage investment in advanced semiconductor manufacturing capability, in an attempt to restore our nation’s leadership in producing the world’s most advanced semiconductor chips. Sen. John Cornyn (R-Texas), Sen. Mark Warner (D-Va.), Sen. Jim Risch (R-Idaho), Sen. Kyrsten Sinema (D-Ariz.), and Sen. Marco Rubio (R-Fl.) introduced the Creating Helpful Incentives to Produce Semiconductors (CHIPS) for America Act (S. 3933) in the Senate. And in the House, Rep. Michael McCaul (R-Texas) and Rep. Doris Matsui (D-Calif.) introduced H.R. 7178, making the bill bicameral and bipartisan – a rarity in Washington.

The CHIPS Act creates a series of incentives for companies to move semiconductor manufacturing back into the United States. These incentives are intended to enable the United States to effectively compete with incentives offered by our global competitors to attract the construction of foundries capable of producing the next generation of semiconductor-based circuits. Although semiconductor circuits were first invented in the United States, only 12% of the global semiconductor manufacturing capacity remains in this country today. Foreign incentives, coupled with previous U.S. economic policy that discouraged U.S. companies from investing domestically, have significantly eroded our leadership position in this area. Congress now recognizes there is a critical need to reinvigorate this domestic industry as a national priority.

In 1965, Dr. Gordon Moore (IEEE Life Fellow), co-founder of Intel, predicted that the number of components in an integrated circuit would double every year, which he later revised to doubling the number of components every two years. Over time, his now famous prediction became known as Moore’s Law. For the last 50 years, Moore’s Law has been the guiding predictor for future expectations of the semiconductor industry. Industry has continued to deliver ever more powerful chips, while decreasing the overall cost and size of electronic systems — allowing innovations that include GPS, the smartphone, computers, and global commerce as we know it today.

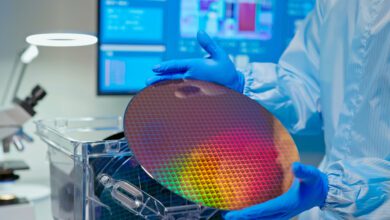

Through relentless technological innovation, we are now at the point where we can produce an integrated circuit containing several billion transistors. However, as we continue to reduce feature size, we are also approaching fundamental physics limits in terms of how much smaller and how much faster we can make these critical components. The cost associated with constructing state-of-the-art foundries capable of producing these modern chips exceeds several billion dollars per foundry. This cost, along with fundamental fabrication challenges, will have a serious impact on our ability to keep up with Moore’s Law.

As a result, improvements in chip technology will become more incremental. As our global competitors continue to advance, it is becoming a matter of national and economic security that the United States regain its lead in producing advanced semiconductors in this country. But to accomplish this task, the United States will have to marshal resources and invest in state-of-the-art fabrication facilities, a skilled workforce, and support the necessary research to do so.

The CHIPS Act provides for a range of federal investment to encourage the next generation of semiconductor manufacturing in the United States, including:

- A 40% refundable income tax credit for semiconductor equipment or manufacturing facility investment through 2024, which tapers off by 2028

- A $10 billion federal program that matches, dollar for dollar, state and local incentives made for the establishment of a semiconductor foundry with advanced manufacturing capabilities

- Up to $12 billion for NIST, NSF, DOD, DOE and DARPA to conduct and promote basic research programs in advanced semiconductor fabrication technology in order to maintain our leadership position in semiconductor technology and innovation

- A new NIST Semiconductor Program to support advanced manufacturing in the United States

- Funds to support STEM workforce development, ecosystem clustering, U.S. 5G leadership, and advanced assembly and testing

The most compelling reason for taking this next bold step is because if we don’t, some other country will. The country that commits itself to establishing and supporting the infrastructure these foundries will require, will reap the benefits of having a source for high-paying jobs in an environmentally friendly industry that provides the core capability for an economic engine of the globe well into the end of the 21st Century. The industries required to support these foundries will also produce thousands of additional jobs, and encourage the establishment of domestic supply chains that use the components supplied by these foundries to fuel that country’s economic future and prosperity.

The cost associated with making this investment is miniscule in comparison to the benefits it will reap for the future of our country. SEMATECH was a not-for-profit consortium established in 1988 as a partnership between the United States and 14 U.S.-based semiconductor manufacturers to address the threat posed by the Japanese industry in the mid-1980s. SEMATECH received funding from the United States for five years that amounted to a total of $500 million. Intel was one of the companies that was involved in this consortium. In 2019, Intel generated a pretax income of $24 billion and paid more than $2 billion in U.S. taxes, or four times the amount of the U.S. investment over five years.

It is time for the United States to make this strategic long-term investment. IEEE-USA applauds the sponsors of the CHIPS Act, and will be actively supporting this legislation.

Will Robinson, an IEEE Senior Member, is IEEE-USA’s vice president of government relations.

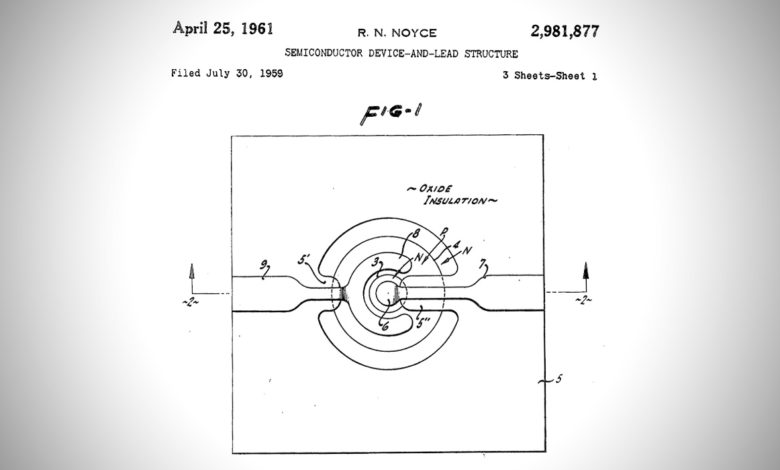

Jack Kilby invented the integrated circuit; Robert Noyce invented the first one using the planar process.

Another case of ‘corporate and white-collar socialism’ . NO.

The targeted companies [Intel TI Micron] have been some of the ‘most profitable’ ones, and should ‘spend their own’ profits. Global Foundries is not even a US corporation; just like Apple is an Ireland? entity.

First, as Robert Bonitz pointed out, the author denied Jack Kilby credit for his invention. I doubt that it is an oversight since this is not the first time I have seen this omission, but I was not expecting this in an IEEE publication; yet, here is another instance where either Kilby or Noyce is not given due credit for inventing the integrated circuit.

Getting to the subject of the article: The author had not preempted the expected criticism from Azmat Malik, given that there are numerous examples of major inventions being made in one country and then decades later the manufacturing being done in several different places across national boundaries. I am sure that in some cases the manufacturing had moved out of the United States, and in some other cases the United States at some point became a major manufacturer of a foreign invention. For example, steam, electric, and gasoline automobiles were all invented in various countries in Europe. If the semiconductor industry had legitimate complaints about unfair practices in other nations then I would expect the US Department of Commerce to have taken that up with the foreign governments and the World Trade Organization. I was expecting Mr. Robinson to give us the history of that, if there is any. By not addressing the broader question of why the CHIPS for America Act is necessary despite the known benefits of globalization, Mr. Robinson has rendered his article rather uninteresting, to say the least.

Right idea, wrong execution, just a give-away to the Companies that caused the problem.